Oem Lamination Press

And speeds up to 2 000 fpm.

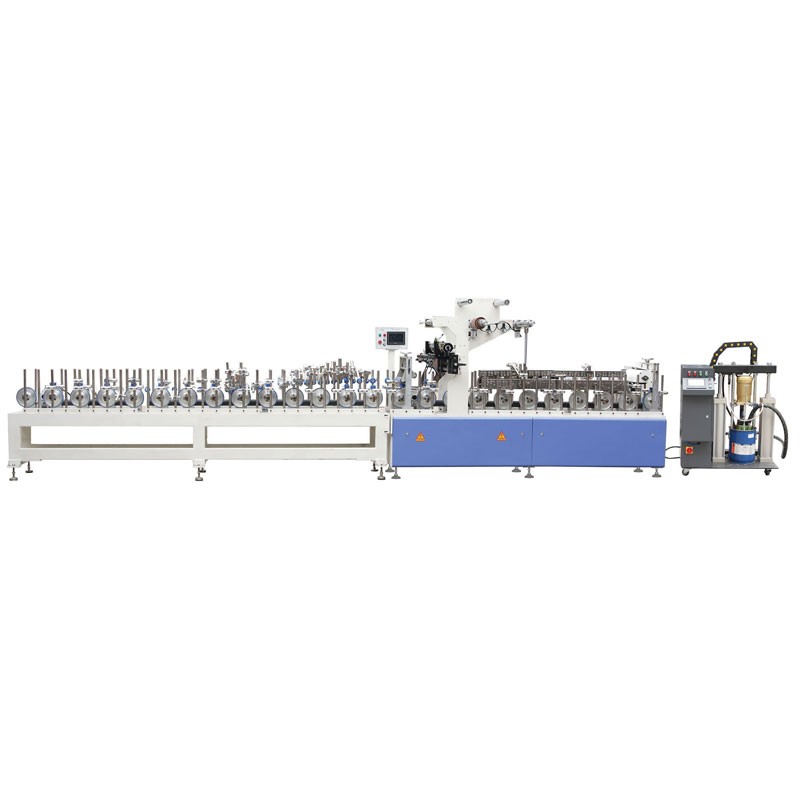

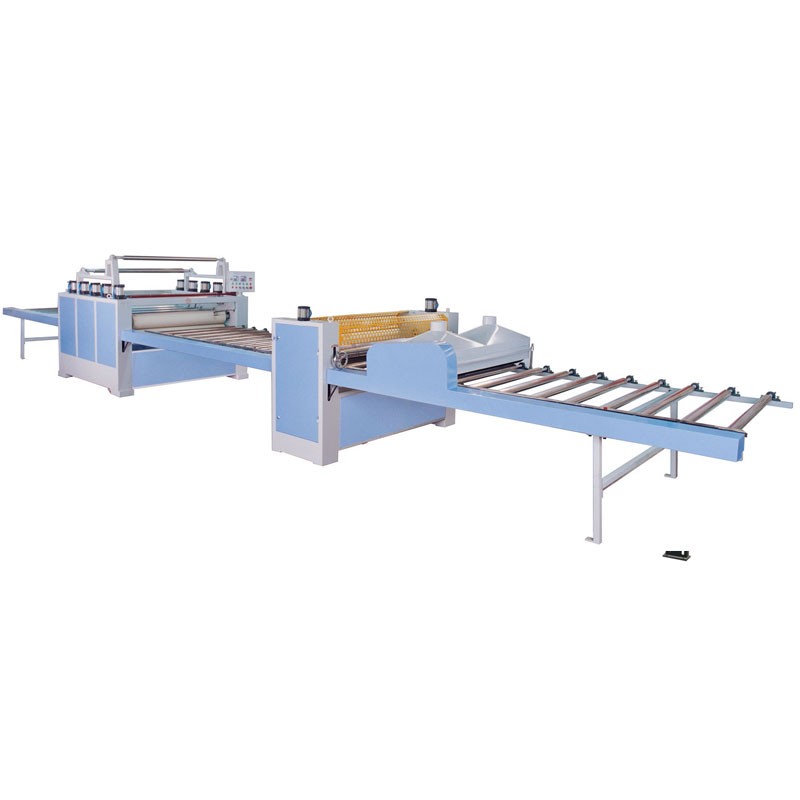

Oem lamination press. Another lamination process uses a lamination press after materials are combined in a thicker structure than film. Used 200 ton wabash hydraulic molding laminating inline press add to quote cart 200 ton wabash 200 3624 2tmx upstroke 4 post 36 x 24 hot plates 1000 f 28461. The dot medical examination. Applications include laminating paper film and foil.

We are a full service hydraulic press service and parts supplier specializing in laminating and compression molding presses. The dot medical examination. Form the smallest leak to full rebuilds we can deliver a job that will far exceeded your expectations. Cirexx international announced today that they have completed installation of two new oem orange engineering manufacturing high temperature lamination press systems.

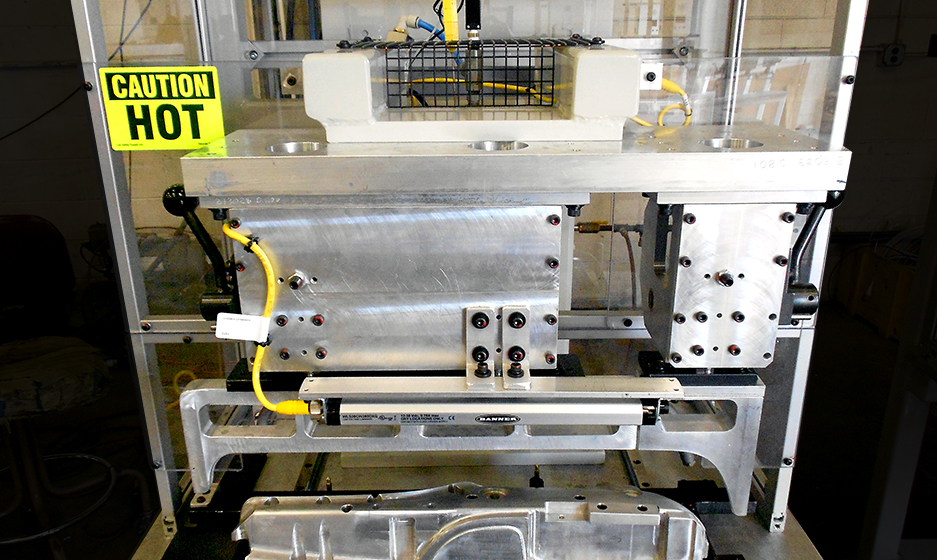

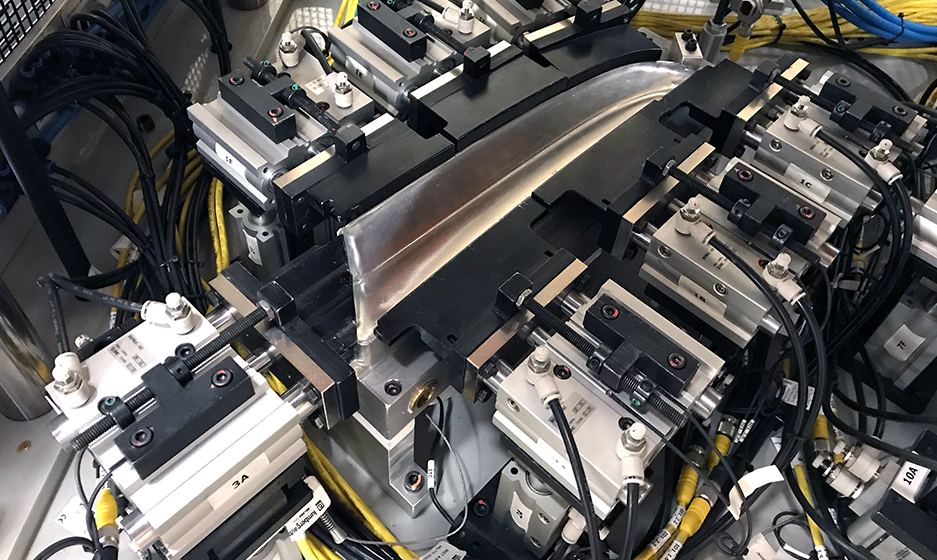

The platens of the laminating press may be heated by steam oil or electrically. Oem designs and manufacturers innovative vacuum and non vacuum hydraulic press and material handling solutions for the pcb aerospace bio mass automotive rubber and other industries. Industrial sized laminating presses feature stacked heating and cooling platens laminating presses operate by heating one opening of the press while cooling the other. Typically this is done to achieve a cosmetic or performance aspect to the face for commercial or industrial use.

The presses have 24 x 30 platens in a vacuum assist chamber and are capable of reaching 600 c. Dry bond laminators wet bond laminators and thermal laminators are available. As an example azdel a glass reinforced thermoplastic composite made with continuous glass mat is produced using an extrusion lamination operation film continuous random orientation glass mat and molten resin are combined in a lamination process using a sandvik double belted. Books 1 10 of 18 1 2 next.

An unofficial guide to commercial drivers medical certification seventh edition. Thus fast lamination results are achieved. An unofficial guide to commercial drivers medical certification seventh edition. Oem focuses on providing the exact solution needed for any product application with presses designed for lamination compression molding composite molding and.

The job of a laminating press is to bond layered materials together to create a stronger material than the original. Many laminating processes involve coating a film textile plastic metal wood or other porous or non porous. Our staff has over 100 years of combined experience in hydraulic press design manufacturing and repair. Occupational environmental medicine.